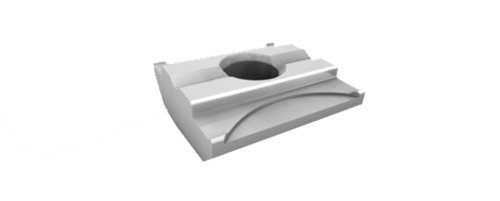

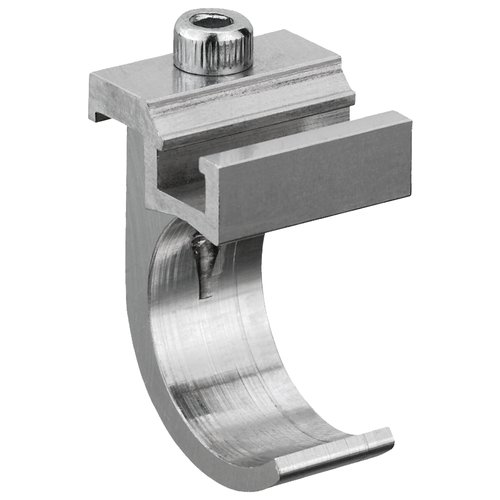

| Piston rod modification | through |

| Functional principle | double-acting |

| Cushioning | elastic |

| Magnetic piston | with magnetic piston |

| Piston diameter | 20 mm |

| Piston rod thread | M8 |

| Standardization | ISO 6432 |

| Stroke | 100 mm |

| Sealing material | Acrylonitrile butadiene rubber,Polyurethane |

| Scraper | Polyurethane |

| ATEX optional | |

| Compressed air connection | G 1/8 |

| Compressed air connection type | Internal thread |

| Standards | ISO 6432 |

| Certificates | ATEX optional |

| Compressed air connection | Internal thread |

| Working pressure min./max. | 1 … 10 bar |

| Ambient temperature min./max. | -25 … 80 °C |

| Medium temperature min./max. | -25 … 80 °C |

| Medium | Compressed air |

| Max. particle size | 50 µm |

| Oil content of compressed air | 0 … 5 mg/m³ |

| Pressure for determining piston forces | 6.3 bar |

| Weight | See table |

| The pressure dew point must be at least 15 °C under ambient and medium temperature and may not exceed 3 °C . The oil content of compressed air must remain constant during the life cycle. Use only the approved oils from AVENTICS. Further information can be found in the “Technical information” document (available in the MediaCentre). |

| Clamping piece for magnetic field sensor necessary |

| ATEX-certified cylinders with identification II 2G Ex h IIB T4 Gb / II 2D Ex h IIIB T135°C Db_X can be generated in the Internet configurator. The operating temperature range for ATEX-certified cylinders is -20 °C … 50 °C. Warning: The front and rear piston rods must not be twisted against one another! |

| Material |

|---|

| Cylinder tube | Stainless steel |

| Piston rod | Stainless steel |

| Piston | Brass, Aluminum |

| Front cover | Aluminum, anodized |

| End cover | Aluminum, anodized |

| Seal | Acrylonitrile butadiene rubber Polyurethane |

| Nut for cylinder mounting | Steel, galvanized |

| Nut for piston rod | Steel, galvanized |

| Scraper | Polyurethane |