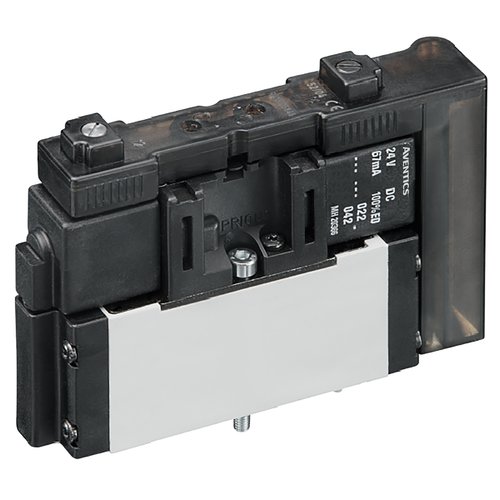

| Switching principle | 2×3/2 |

| Version | Spool valve, positive overlapping |

| Housing | Polyoxymethylene |

| Sealing material | Acrylonitrile butadiene rubber,Hydrogenated nitrile butadiene rubber,Polyurethane |

| Protection class | IP50 |

| Number of wires | 2-pin |

| Port size | Industrial plug connector |

| Type | Plug |

| Nominal flow Qn | 175 l/min |

| Compressed air connection input | Ø 4 |

| Compressed air connection output | Ø 4 |

| DC operating voltage | 24 V |

| Activation | Electrically |

| Version | Spool valve, positive overlapping |

| Activation | Electrically |

| Pilot | Internal |

| Sealing principle | Soft sealing |

| Working pressure min./max. | 3 … 7 bar |

| Ambient temperature min./max. | -10 … 50 °C |

| Medium temperature min./max. | -10 … 50 °C |

| Medium | Compressed air |

| Max. particle size | 5 µm |

| Oil content of compressed air | 0 … 5 mg/m³ |

| Nominal flow Qn | See table |

| Protection class acc. to DIN EN 61140 Electrically | Class III |

| Protection class with connection | IP50 |

| Protective circuit | Z-diode |

| LED status display | Yellow |

| Duty cycle | 100 % |

| Typ. switch-on time | 12 ms |

| Typ. switch-off time | 15 ms |

| Generic emission standard in accordance with | EN 61000-6-4:2002 |

| Generic immunity standard in accordance with | IEC 61000-6-2:2005 |

| mounting screws | M3 |

| Mounting screw tightening torque | 0,5 Nm |

| Weight | 0,064 kg |

| The min. control pressure must be adhered to, since otherwise faulty switching and valve failure may result! The pressure dew point must be at least 15 °C under ambient and medium temperature and may not exceed 3 °C . The oil content of compressed air must remain constant during the life cycle. Use only the approved oils from AVENTICS. Further information can be found in the “Technical information” document (available in the MediaCentre). A duty cycle of 100 percent is only valid for single valves. |

| Material |

|---|

| Housing | Polyoxymethylene |

| Seals | Acrylonitrile butadiene rubber Hydrogenated nitrile butadiene rubber Polyurethane |